The modico® stamp technology

We explain how the modico® puts an imprint on the paper.

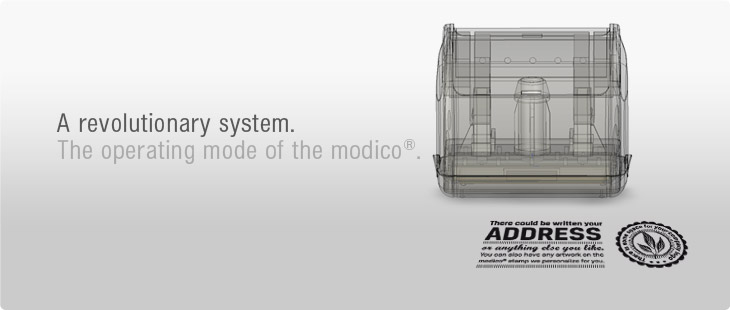

How the modico stamp works

Child`s play and quick as a flash

The flash-technology is the simple principle used for modico®. It replaces the old processes of stamp making: the production is clean, easy and safe. The stamp is created by exposure of a microporous text plate with flashlight. The ink cartridge lies behind the text plate made of a microporous, special foamed material that stays ink penetrable at the unexposed areas. By pressing the stamp on the paper, the ink will be transferred through those areas.

A new modico® is created in 3 minutes. Its imprint is razor-sharp. Its resolution gains up to 600 dpi. Graphics, grey scales, photos, personal signatures and fonts down to 4,5 points are reproduced precisely. An intelligent technology that makes a profit margin of up to 80 percent possible.

All you need is a laser printer, the modico-exposure-unit and a little bit of creativity.